Introduction

How does the Agro Bag work?

Simple service and full flexibility

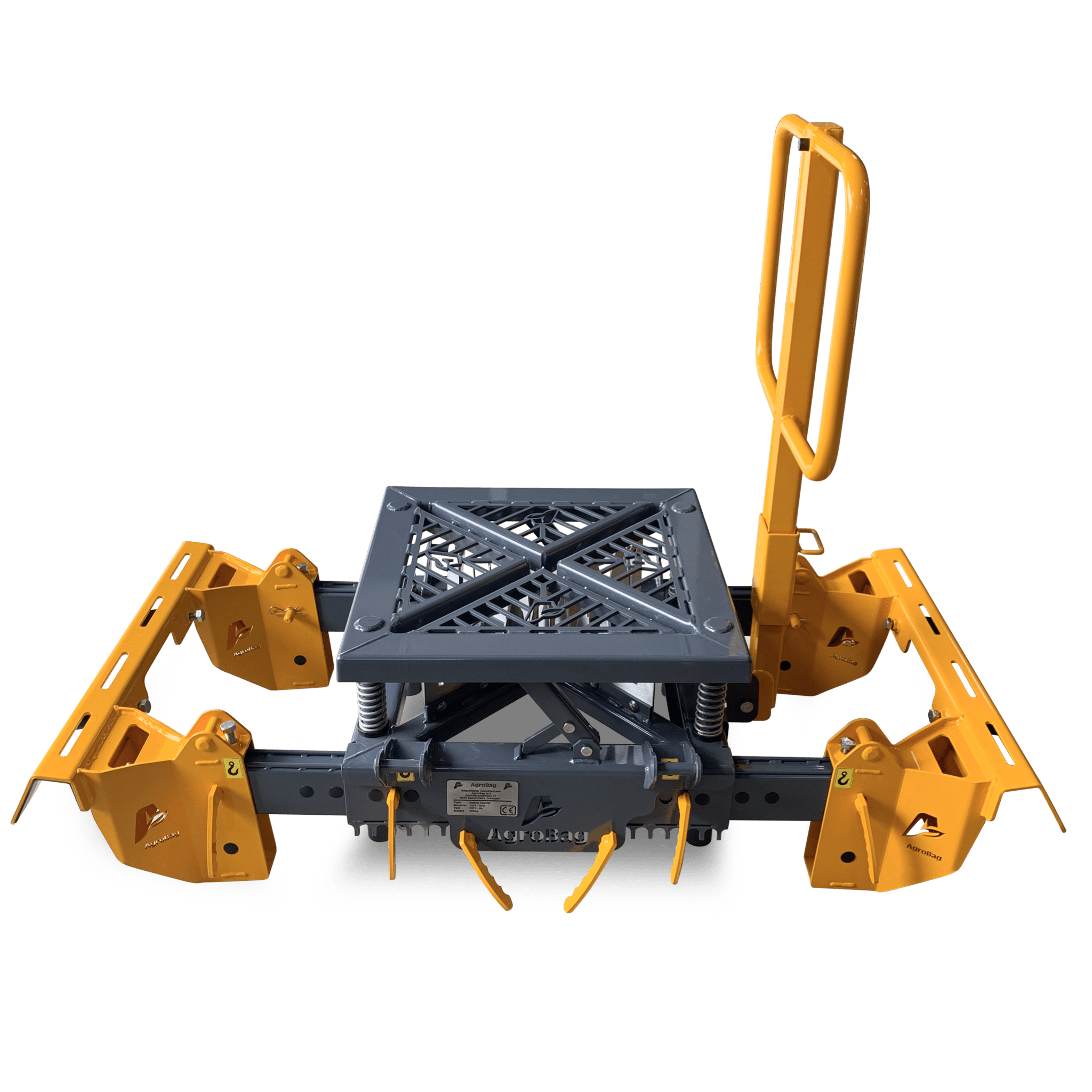

With Agro Bag we’ve tried to solve a general need in the agriculture industry with a faster, easier and safer opening of big bags in the fertiliser spreader. Although Agro Bag works in a simple way the result of this solution is a combination of complicated, mechanical technique mixed with a design of soft edges and shapes to achieve a nice look as a component for your fertiliser spreader.

Emptying big bags can now take place safely and directly from inside the tractor cabin, enabling farmers to handle and empty many big bags faster and more effectively while reducing on the physical strain on the farmer himself and the medical risks of inhaling fertiliser dust when filling fertiliser spreaders.

Benefits

Our costumer’s experience with Agro Bag

Faster unloading

With Agro Bag you can expect reduction in time while filling your fertiliser spreader as you can handle all the practical work from inside the tractor cabin during the entire filling and never have to leave it to empty big bags with a knife for example.

In some cases, you can save a man completely away on the farm if two men are put on the task of filling the fertiliser spreader. The extra man then instead has the opportunity to initiate a new task in parallel with the emptying of big bags which saves a lot of time on the farm and provides greater flexibility.

One time investment

Our focus during the development of Agro Bag has especially been to maintain low cost of ownership while maintaining efficient and fast emptying as well as excellent reliability.

We know that on farms there are already a lot of different operating costs for both machines and tools, and we have therefore designed a 100 % mechanical system that offers a big output and a long service life with low maintenance costs.

Moreover, we have made Agro Bag extra strong by using a large material thickness on our steel as well as durable paint that can withstand being in a raw environment with fertiliser. Simultaneously it’s easy to replace the many different parts of the tool.

The farmers operating savings starts from day one

- Effective and fast unloading (approx. 30% faster)

- Cost-effective handling – Higher productivity.

- Lower operation- and maintenance costs.

- Operational stability and reliability.

Improved working conditions

When using Agro Bag the farmer will quickly find out that it is not only efficiency and productivity which get affected. By using Agro Bag, the working environment can be improved as the tool requires less physical effort and causes less damaging and longsighted physical impact on the body.

During the emptying of a big bag the farmer will never have to stay near the bag which reduces the risk of:

- fall accidents from the fertiliser spreader

- physical strains

- medical consequences by inhaling fertiliser dust.

A single operator can easily fill an entire fertiliser spreader without leaving the tractor cabin and therefore eliminates the repetitive physical movements that normally occur during filling. Agro Bag therefore helps making it a less demanding process.

Less risk of injuries due to the fertiliser spreader

When emptying the big bag with a knife in the bottom of a bag there will be a big load for the fertiliser when it hangs a few meters above the fertiliser spreader. In some cases, this can be a disadvantage if there are large lumps inside the bag, which runs out and fall directly into the bottom of the fertiliser spreader when cutting the bag. In some cases, it can harm the fertiliser spreader or wear on the construction.

With Agro Bag as a tool the emptying will take place by lowering the sack over the platform to release coil spring after which the knives cut up the bottom of the sack. When the springs are fully released, potential lumps in the bag don’t have a free expiration as the platform blocks for fallout in the fertiliser spreader. The farmer then has the option of cutting the lump into pieces by lifting and immersing big bag several times to avoid potential damage to the fertiliser spreader.

Innovation og perfection

Semi automatic unloading of big bags

Agro Bag is a safe and user-friendly tool for the farmer who wishes to easy the unloading of bigbags and improve the work environment during the filling of the fertiliser spreader. The tool is both a stabil and reliable operation solution with low maintenance costs which gives a bigger flexibility and optimizes the daily tasks in the agriculture.

Agro Bag

Key functions

- 1. Security system

- 2. Big bag stop

- 3. Knife system

- 4. Locking system

- 5. Adjustable brackets

- 6. Flex system

- 7. Adjustable profile pipes

- 8. Lifting hooks

- 9. Safe installation with M-16 bolts

- 10. Brackets

Technical overview

Compatible models

The Agro Bag platform is universal but all brackets are individually dependent on the specific fertiliser spreader to make sure that Agro Bag fits all the angles of the edge. If you can’t see your fertiliser spreader down below please contact us.

Bredal

- F2

- F4

- F8

- F10

- K105

Amazone

- ZA-TS

- ZG-TS

- ZA-V

Bøgballe

- M60W BASE/PLUS

- M45W BASE/PLUS

- M35W BASE/PLUS

- L20W BASE/PLUS

- M45 BASE/PLUS

- M35 BASE/PLUS

- L20 BASE/PLUS

- L15 BASE/PLUS

Kverneland

- KVERNELAND EXACTA EL

- KVERNELAND EXACTA CL

- KVERNELAND EXACTA CL EW

- KVERNELAND EXACTA CL GEOSPREAD

- KVERNELAND EXACTA HL

- KVERNELAND EXACTA TL

- KVERNELAND EXACTA TL GEOSPREAD

- KVERNELAND EXACTA TLX GEOSPREAD

High tip wagon

- UNIVERSAL 50MM BESLAG

- UNIVERSAL 95MM BESLAG